Every year McHale balers produce over 75 million bales of forage for farmers and contractors. To maximise the feed value of this forage it is important that grass crops are cut when the sugar content is highest, and that the mower leaves clean crop stubble and produces quality forage free from impurities.

Download Product PDFMcHale offer farmers and contractors a choice of combination mowers. The McHale Pro Glide B9600 is equipped with two 3.4m cutter bars and can cut up to 9.6m when operating with an F3100 front mower

The smaller model, the McHale Pro Glide B9000 is fitted with 3m cutter bars and has a cutting width of up to 8.75m when coupled with an F3100 front mower.

All mowers are fitted with steel tine conditioners and benefit from several novel features resulting in better ground following ability and quicker reaction times to changes in ground conditions to deliver a clean cut with uncontaminated crop.

| Springs Provide Excellent Ground Following Ability | Hydraulic Width Adjustment | |

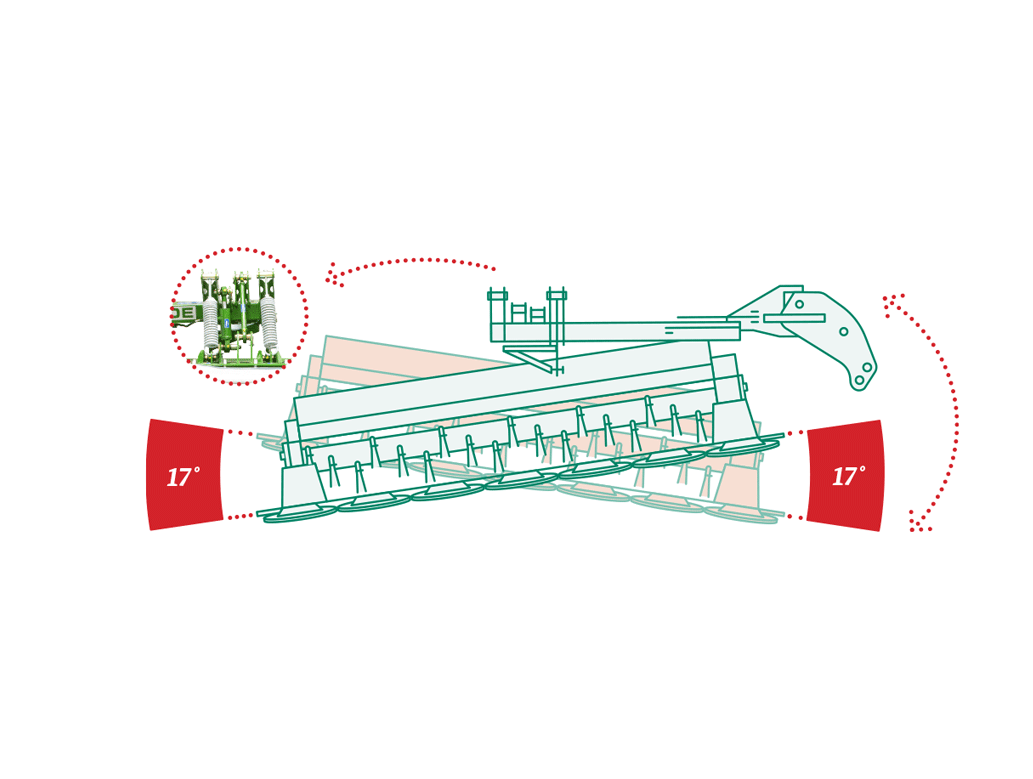

| Patented Constant Ground Pressure | 17º Transverse Pivot Range (Left / Right Movement) |

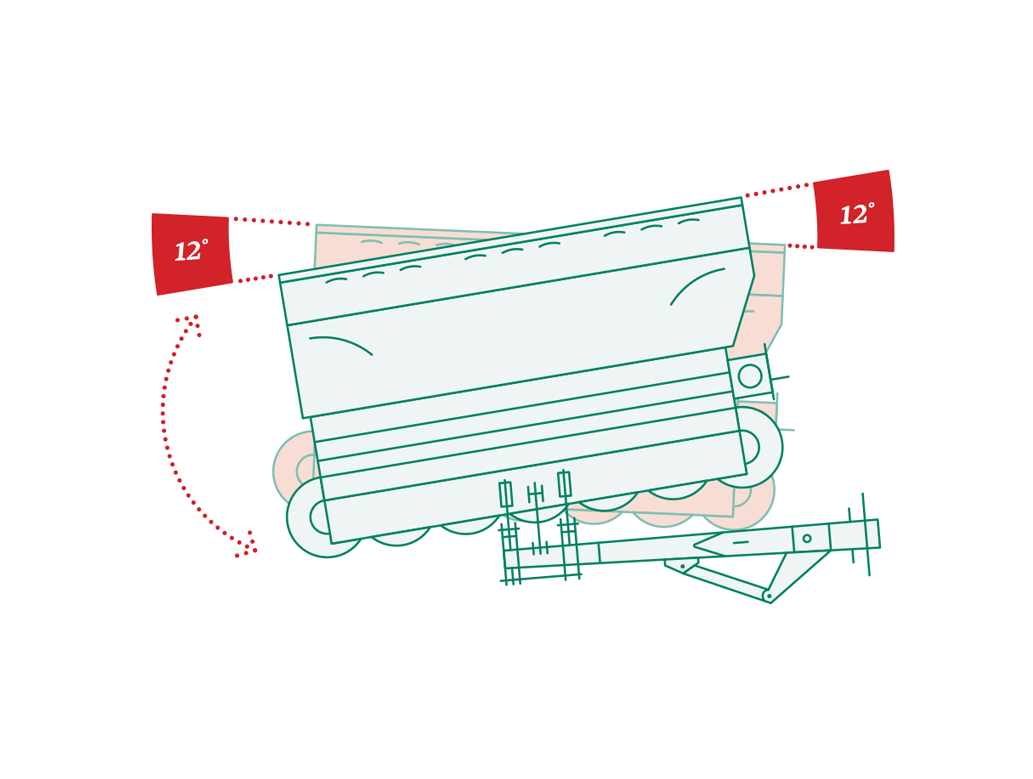

12º (Forward / Back Movement) |

| Unique Cutter Bar Protection | 3D Ground Contour Tracking | Vertical Transportation and Parking |

| Pull Type Mowing System | ||

The left/right transverse movement means the cutter bar maintains a clean cut as it smoothly glides over humps and hollows in the ground.

This movement ensures a precision floatation of the cutter bar for a cleaner cut in all ground conditions.

Most rear mowers have a central pin which allows the mower to move left and right to adjust to changes in ground condition.

The McHale Pro Glide is different in that it is fitted with a patented 3D ground tracking suspension unit, which ensures that the Pro Glide cutter bar delivers better cutting performance by:

Read less

Hydraulic Width Adjustment is available as an optional extra on the McHale Pro Glide B9000 and B9600 combination mowers. The operator can hydraulically adjust the width position of the rear mowers to eliminate striping on slopes and curves. The hydraulic rams integrated into the mower beams shift the cutter bars sideways either together or independently to allow for overlap on each mower.

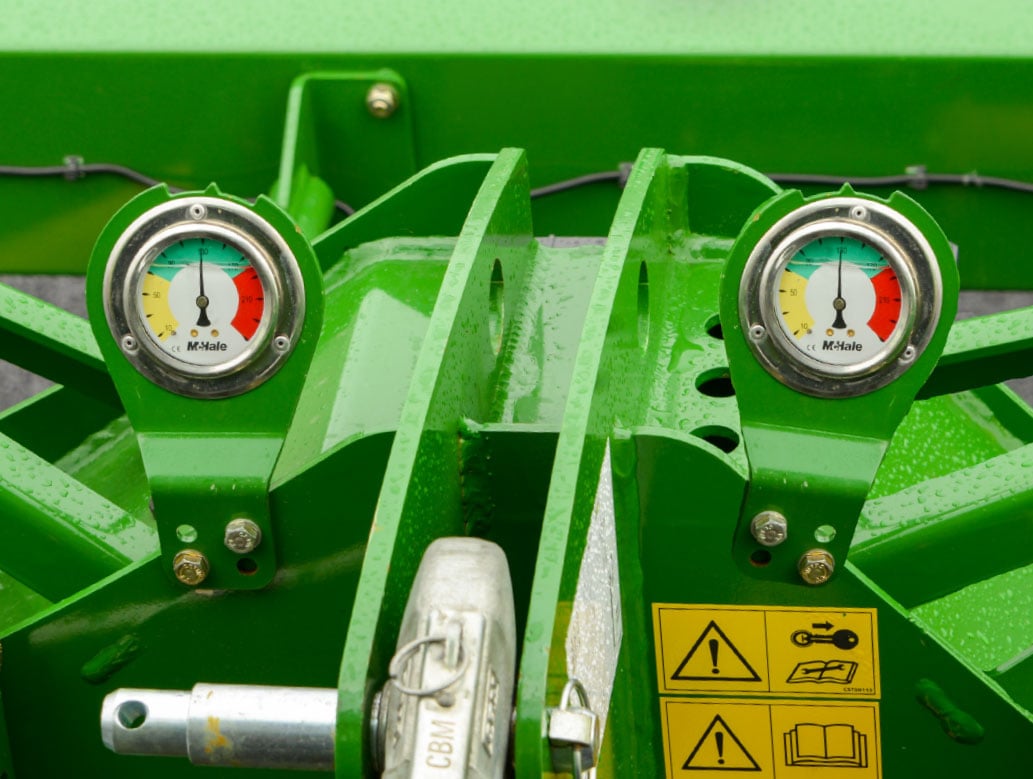

On the Pro Glide rear mowers, the cutter bar ground pressure can be set from the tractor cab. The working pressure is visually displayed on the clock which is mounted on the headstock. Once the desired pressure is selected the cutter bar working pressure can be isolated from the tractor hydraulics with a mechanical tap.

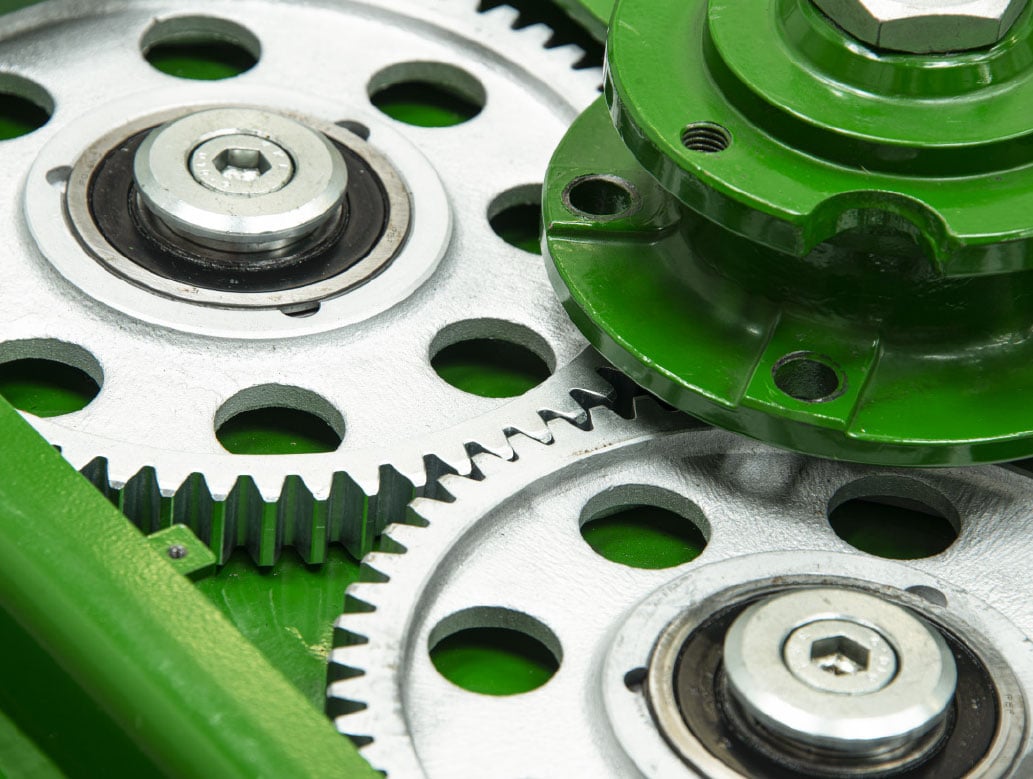

Pro Glide mowers are fitted with an extremely strong fully welded cutter bar. All 3m cutter bars are fitted with 7 discs while all the 3.4m cutter bars are equipped with 8 discs. The discs are driven by auxiliary gears and as the cutter bar is welded and filled with oil, the gear drive operates in a continually lubricated environment which ensures quiet operations and maximum life.

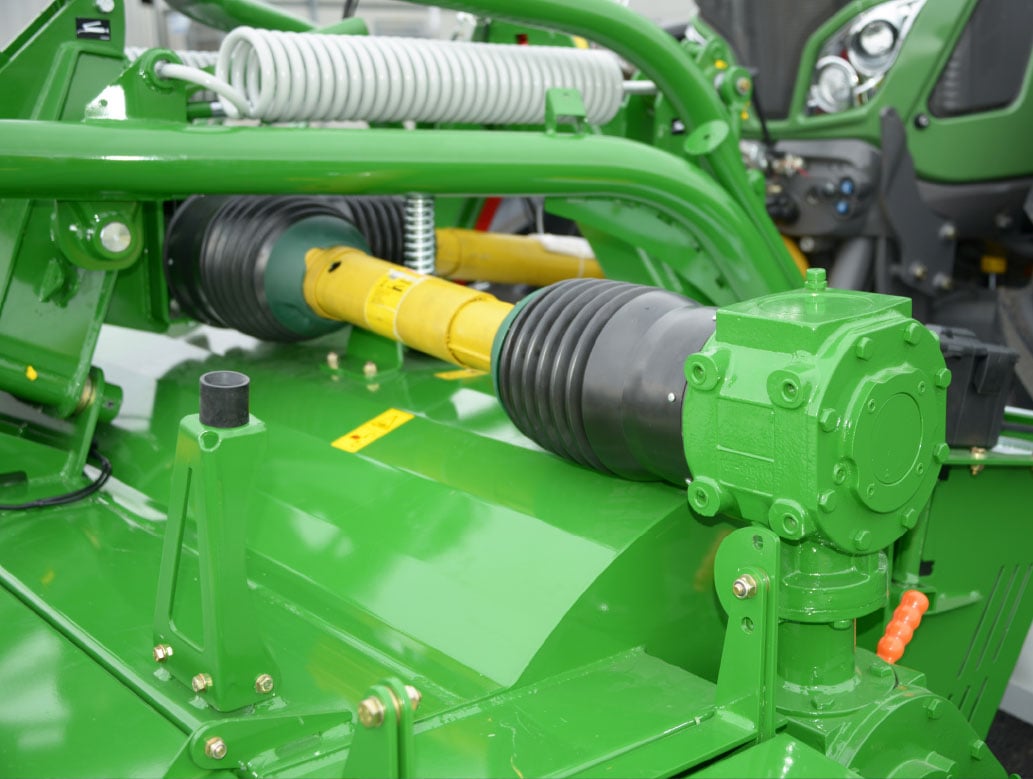

The Pro Glide cutter bar is powered by a heavy duty right angle gearbox that is positioned behind the inner mowing disc. The positioning of the gearbox allows the operator to mow into corners and over rough terrain without experiencing problems.

The Pro Glide cutter bar has been designed so the rounded low profile front edge lets the fully welded cutter bar glide smoothly over the ground. The slanted leading edge of the cutter bar allows for clean forage separation and reduces ground contamination.

In the cutter bar, large heavy duty drive gears transfer the power to auxiliary gears which power the individual discs. The auxiliary gears which drive the individual discs are mounted in a forward position on the cutter bar which deliver maximum cutting performance even when working in lodged crops.

The mowing discs are specifically designed to maximise crop flow. All mowing discs are equipped with two blades that are angled to ensure a clean cut. The blades orbit with a generous overlap to deliver an uncontaminated swath. Each mowing disc has its own individual protective safety mechanism, if a collision occurs, the mechanism will shear in order to protect the drive.

The 110mm mower blades rotate and overlap very close to the surface of the cutter bar and the counter blade to deliver a clean cut. With the aid of the specially designed lever, the blades on the McHale Pro Glide mower can be changed quickly and easily. A weatherproof toolbox is mounted on the mower for storing spare blades and tools.

The McHale Pro Glide comes standard with a steel tine conditioner to condition the grass as efficiently as possible. In order to increase wilting time and decrease the exposure of the forage to the weather, the McHale Pro Glide prepares a uniform swath by conditioning across the working width of the mower.

The conditioner is driven by a mechanical gearbox. Conditioning speeds can be adjusted between 700 and 1000 rpm with the simple pull of a lever. The position of the steel tines allow for powerful conditioning, which ensures the McHale Pro Glide range can deliver fast uniform wilting. Should a tine come into contact with a foreign object they pivot out of the way.

The operator can select from six adjustments for adjusting conditioning intensity. The operator also has the option to set the deflection plates and leaves the swath in a wide or narrow formation.

The McHale Pro Glide mower range is fitted with a heavy duty 1,000 rpm drive line. Power is transmitted through heavy duty star tubing and the shaft is protected by the Walterscheid P Line range of drive shafts. These drive shaft covers allow for very easy and simple access to all greasing points without the need for any untidy anti-rotation chains on the shaft guards and results in improved operator safety by delivering a longer service life.

The McHale Pro Glide folds vertically to position itself behind the centre point of the tractor for safe transport. This position allows for the mowers to distribute their weight across the tractor for ease of transport on the road while also providing the driver with a clear rear view. The B9000 & B9600 combination mowers come as standard with a vertical parking stand. By simply unfolding the parking legs, the mowers can be parked vertically when not in use or for winter storage to avoid taking up shed space.

Every year McHale balers produce over 75 million bales of forage for farmers and contractors. To maximise the feed value of this forage it is important that grass crops are cut when the sugar content is highest, and that the mower leaves clean crop stubble and produces quality forage free from impurities.

The McHale Pro Glide range of mowers has been developed to deliver superior floatation and ground following. The range is fitted with patented ground adaption technology which delivers 3D ground tracking that allows the mower to easily mow on rough or undulating terrain and still deliver optimal results.

D N Crofts & Son are a family run firm with over 65 years’ experience in the agricultural industry. The company are experts in haulage, contracting and all aspects of hay and straw – from production to distribution and storage. Their fleet currently includes a McHale Fusion 3 Plus, McHale Pro Glide F3100 & B9000 Mowers and a McHale 998 High Speed.

Olivia Charles caught up with Jason Crofts to hear how the business developed and how McHale machinery are continuing to help the grow their business

| Transport Width | 2.98m (117″) |

| Transport Length | 2.2m (87″) |

| Transport Height | 4m (158″) |

| Weight | 3,350kg (7385lbs) |

| Cutting Width | 9.1m–9.6m (358″–378″) including Front Mower |

| Swath Width | 1.3m – 2.7m (51″-106″) |

| Number of Cutting Discs | 16 (8×2) |

| Total Number of Blades | 32 (2 blades per disc) |

| Cutting Height | 25mm – 75mm (1″–3″) |

| Cutting Disc Speed | 3,200 rpm |

| Cutting Blade | Quick Change |

| Hydraulic Width Adjustment | Optional |

| Counter Balance Weights | Not Applicable |

| Conditioner Type | Steel Tine Conditioner |

| Conditioner Speed | 700 / 1000 rpm |

| Minimum Power Requirement | 185kW / 250HP (including Front Mower) |

| Linkage Attachment | CAT III or CAT IV (Rear) 3-Point Linkage |

| PTO Speed | 1,000 rpm |

| Lighting | LED Lighting: 12 V/7-pin socket |

| Hydraulic Systems | 3 Double Acting Hydraulic Supply with Float (Minimum)

& Single Acting Hydraulic Supply (Optional) |

| Minimum Pressure | 180 bar (2,610 psi) |

| Minimum Hydraulic Flow Rate | 40 l/min (8.79 gal/min) @ 180 bar (2,610 psi) |

| Capacity | 10.5 ha/h (26 acres/hour) |