THE MOST ADVANCED INTEGRATED BALER WRAPPER RANGE

The McHale Fusion range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained. Our specialist team of engineers have maximised machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion range of machines surpasses all your baling and wrapping expectations.

These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion range of machines to offer durability, reliability and high output to the end user.

Download Product PDFThe MCHALE FUSION VARIO PLUS is a fully automatic integrated baler wrapper which can apply film or net wrap to the barrel of the bale, delivering optimum bale shape and bale density. The Vario Plus can provide high quality fodder through the use of the film binding system, resulting in better quality silage and easier feed out. This machine provides a number of benefits as the task of baling and wrapping can be carried out using one machine. There is also a labor saving, as one operator, one tractor and one machine can complete baling and wrapping duties. The McHale Fusion Vario Plus also has the ability to make bales of hay and straw from 0.6m to 1.68m (2’–5’6″) but in haylage or silage, it produces bales from 1m to 1.45m (3 ‘ 3 “–4 ‘8 “) to allow for wrapping.

It features two unique patents; a patented bale transfer system and a patented vertical wrapping ring. The machine is ISOBUS compatible and can be operated through the tractor terminal or ISO-Play 7 or 12 terminals.

| 2.1m Profi-Flo Pick-Up | Film or Net Binding | ISOBUS/ ISO-Play |

| 2x Inbuilt Camera System | Drop Floor Unblocking System | Double Drive Variable Bale Chamber |

| 15 Knife Chopper Unit with Heavy-Duty Rotor | Single Belt Bale Chamber with Endless Belt | Bale Shape Assist Indicators |

| Patented Bale Transfer Delivering Higher Output | High Speed Vertical Wrapping Ring | Spring Tine Crop Roller |

Film Binding

The concept of putting film on the barrel of the bale is known as “Film Binding Technology.” The plastic, which is applied to the barrel of the bale forms an additional layer of wrap across the largest surface of the bale, whilst also binding the bale together.

The film which is applied to the barrel of the bale can be stretched according to the manufacturers recommendations which is a higher ratio than can be achieved with net wrap. This additional layer of film on the barrel of the bale provides higher quality silage as the film can be stretched more than net. This in turn, expels more air, resulting in better silage quality.

By using film to bind the bale together, removal and recycling of the film is made easier as the farmer is only left with one form of waste to recycle and can avoid the unpleasant and time consuming job of separating net from the plastic.

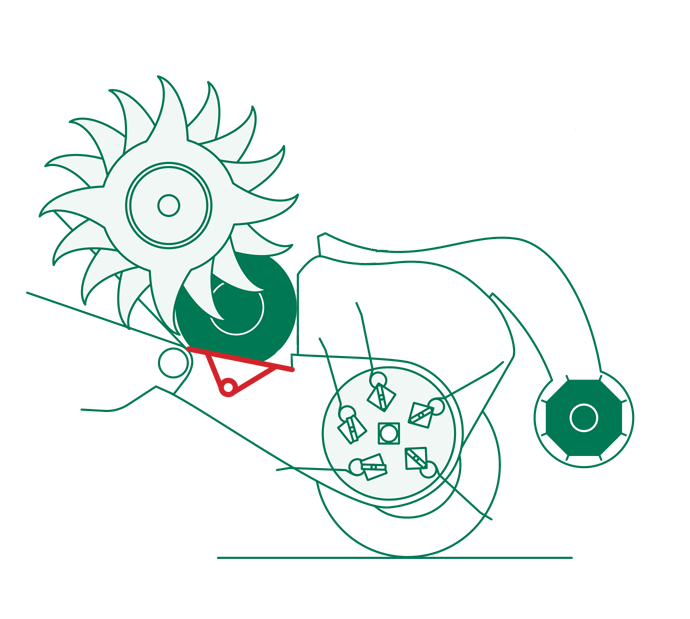

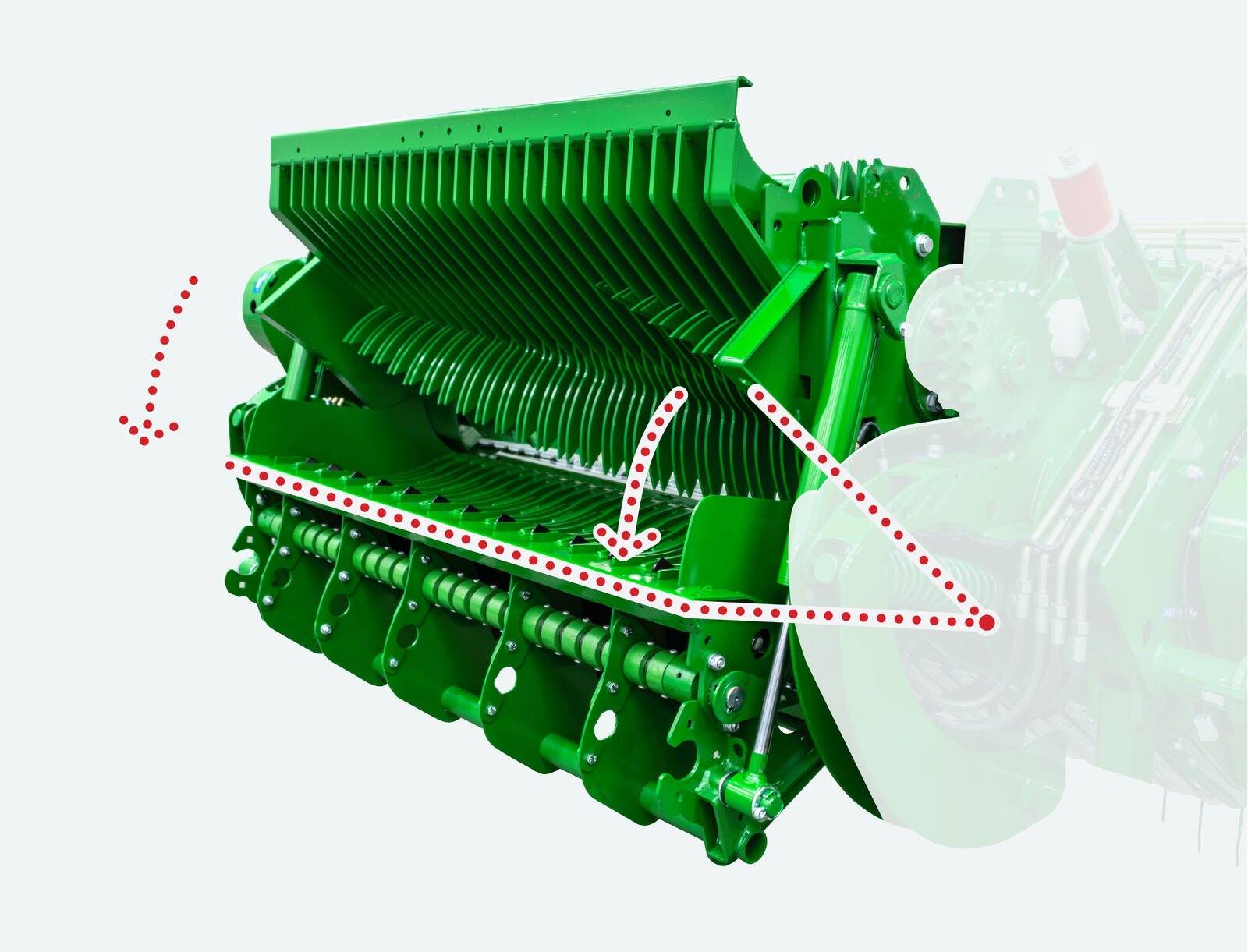

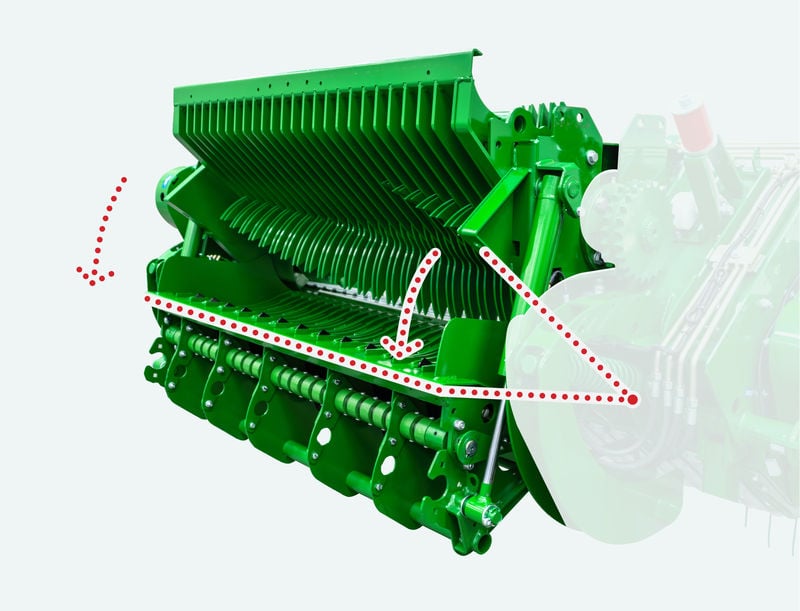

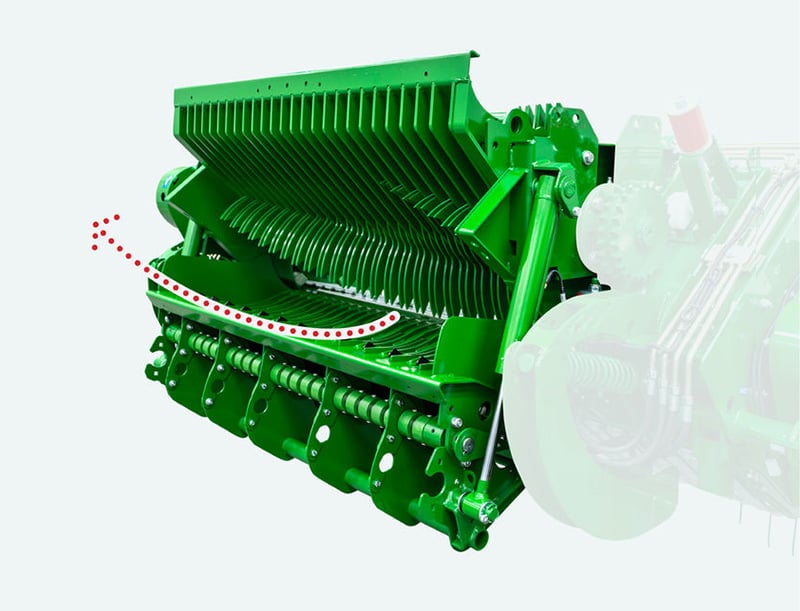

Patented Bale Transfer

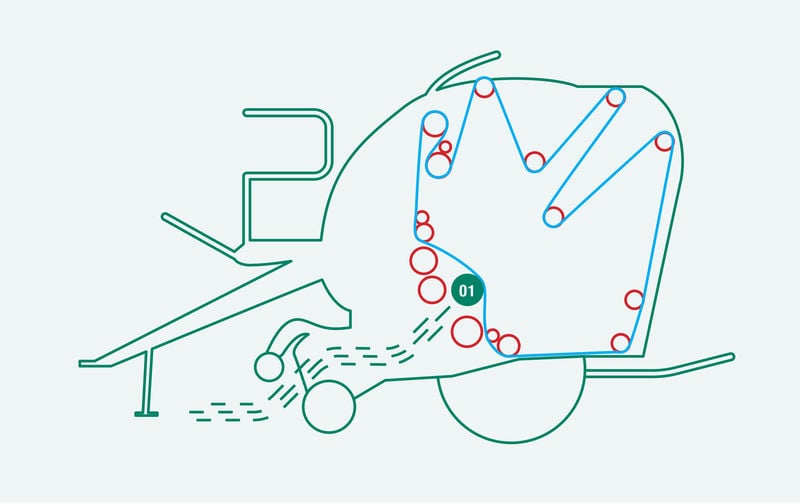

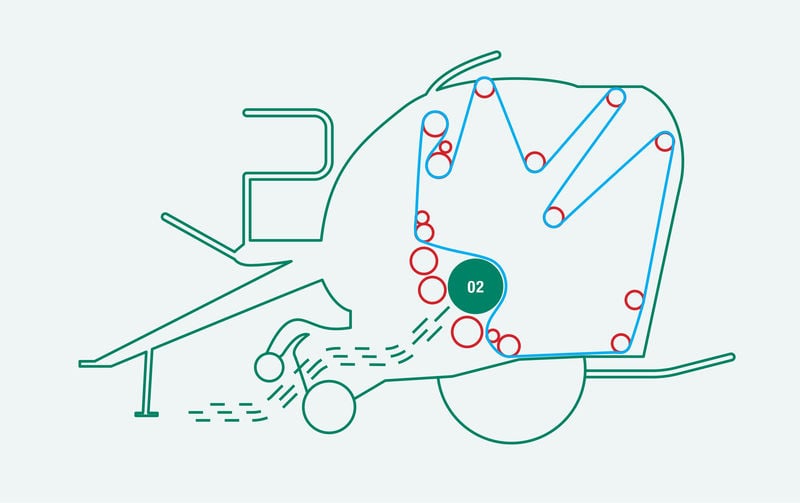

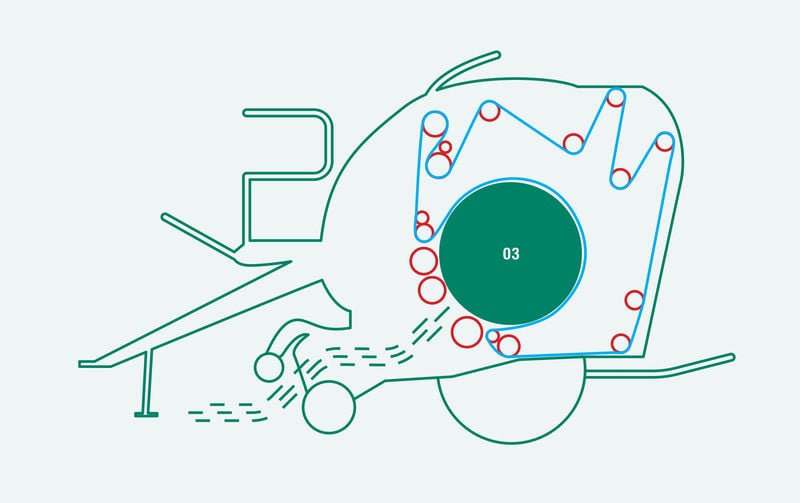

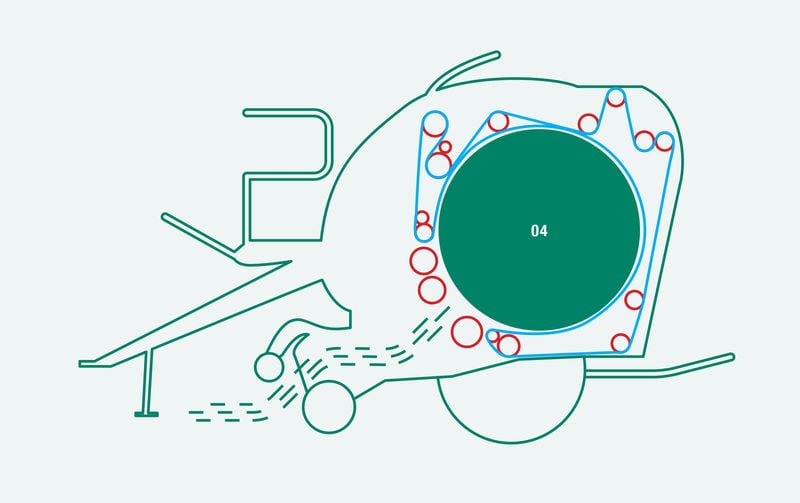

When the bale is bound in the bale chamber, the bale chamber splits horizontally. As the top section of the bale chamber moves up, the lower section of the bale chamber simultaneously moves up and out, transferring the bale onto the wrapping platform.

Control Terminals

The McHale Fusion Vario Plus is fitted with ISOBUS as standard. For customers without an ISOBUS tractor, an optional ISO-PLAY 7 or ISO-PLAY 12 terminal can be used. Through the ISOBUS tractor’s terminal or McHale’s ISO-PLAY terminals, the operator is provided with clear indicators of machine performance and allows for increased levels of monitoring, through the graphic display.

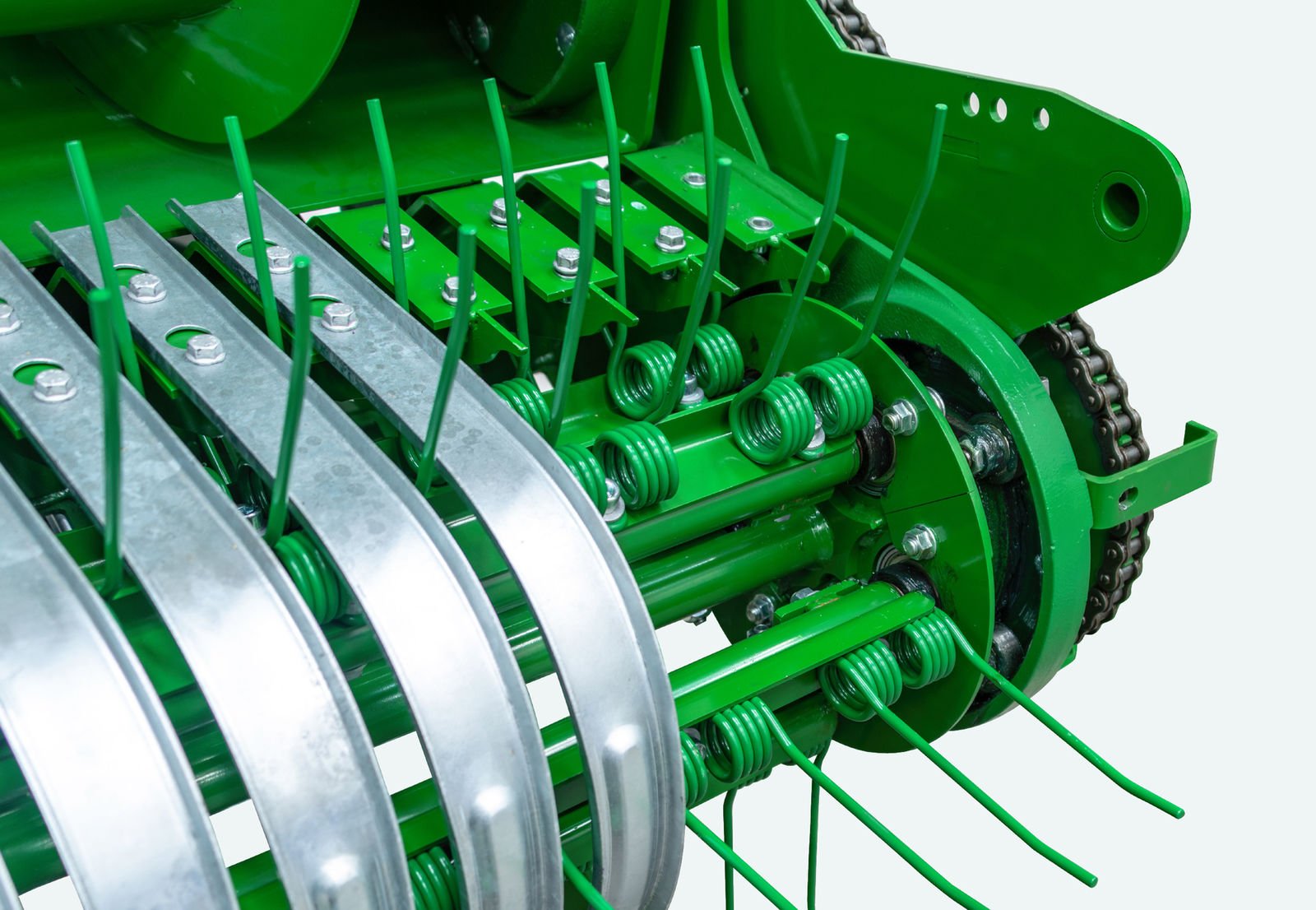

McHale have created their highest output pick-up for the Fusion range. The new Profi-Flo pick-up has been designed to increase crop intake through more efficient crop flow and has been engineered to ensure end users are operating with a high-performance pick-up that is designed to suit various working conditions.

Over the last decade, McHale has designed and developed various types of pick-ups. After extensive testing, McHale decided it will offer customers the choice of 2 pick-up options depending on their working conditions:

As standard, a cam operated 2.1m high-intake galvanised pick-up ensures excellent ground cleaning in all types of crop. The cam pick-up runs on a cam track that is fitted with double raced cam bearings to stand up to the most testing of conditions.

All cam pick-ups across the McHale Fusion range are fitted with 5 tine bars for excellent ground cleaning, while new side bands ensure a continuous delivery of crop to the bale chamber.

A side inspection port allows the operator to quickly check and change the cam bearings if needed.

A 2.1 m camless pick-up is available as an option on all machines in the Fusion range. The camless pick-up has six tine bars to provide excellent ground cleaning and fast delivery of crop to the bale chamber. The camless pickup has been designed to increase output and reduce levels of maintenance.

The vertical wrapping ring on the Fusion Vario Plus is fitted with two 750 mm dispensers, which take 18 seconds to apply 4 layers of film and under 25 seconds to apply 6 layers of film using both dispensers. This means the wrapping platform is always waiting for the next bale.

The dispensers are fitted with film break sensors, which notify the operator through the control terminal in the tractor cab if one or both dispensers run out of film. If one dispenser runs out of film, the machine will continue working by automatically slowing bale rotation, increasing the number of rotations of the wrapping ring to ensure that the bale is wrapped correctly. These sensors are now fitted with removable batteries which can be easily replaced.

Read lessIn normal working conditions, the ever-efficient wrapping process is always completed ahead of the baler, meaning that the wrapping platform is always ready and waiting to receive the next bale.

External Control Keypad

The McHale Fusion Vario Plus comes fitted as standard with an external control keypad. This keypad allows the operator to control the following functions:

• Indexing of the wrapper

• Wrapper Start / Pause

• Rear Wrapping Roller Up / Down

• Rear Work Light

• Internal Panel Lighting

There is also 2 spare buttons which are customisable on the control terminal.

The vertical wrapping ring on the Fusion Vario Plus is fitted with two 750mm dispensers, which take 18 seconds to apply 4 layers of film and under 25 seconds to apply 6 layers of film using both dispensers. This means the wrapping platform is always waiting for the next bale.

Film can be loaded from the left hand side of the machine. After loading film on the first dispenser, the operator can push the index button and the dispensers will then rotate around and automatically stop at the loading position for the second dispenser. This allows the operator to easily load the second roll of film.

New panel lighting has been added to the McHale Fusion Vario Plus to aid the operators when changing rolls of film in the dark. These lights are neatly fitted underneath the side panels of the machines and can be switched on/off from the control terminal or the rear keypad on the machine.

The dispensers are fitted with film break sensors, which notify the operator through the control console in the tractor cab if one or both dispensers run out of film. If one dispenser runs out of film, the machine will continue working by automatically slowing bale rotation, increasing the number of rotations of the wrapping ring to ensure that the bale is wrapped correctly. These sensors are now fitted with removable batteries which can be easily replaced.

On the last rotation of the wrapping cycle, the cut and holds extend out and the wrapping film is gently supported in the cut and hold rails, once supported the cut and hold gathers the wrapping film to one point where it is cut and held. By gathering the plastic to one point, this system makes the Fusion Vario Plus’s performance much more reliable, particularly in hot or wet conditions.

All McHale Profi-Flo pick-ups come with a number of standard features that include:

All McHale cam pick-ups have heavy-duty formed tine supports to ensure long service life, while all camless pick-ups are fitted with a fully welded tine bars. All Profi-Flo camless pick-ups are fitted with two extra columns of tines.

On the Profi-Flo pick-up, the tine bands and feed augers are positioned close to the rotor to improve crop flow from the outside of the wide pick-up. Tapering the augers with 45° ends and removing the steel hydraulic pipes above the pick-up has resulted in a massive reduction in the potential for blockages to occur due to lumps, which ensures a consistent and even crop flow for producing high density bales.

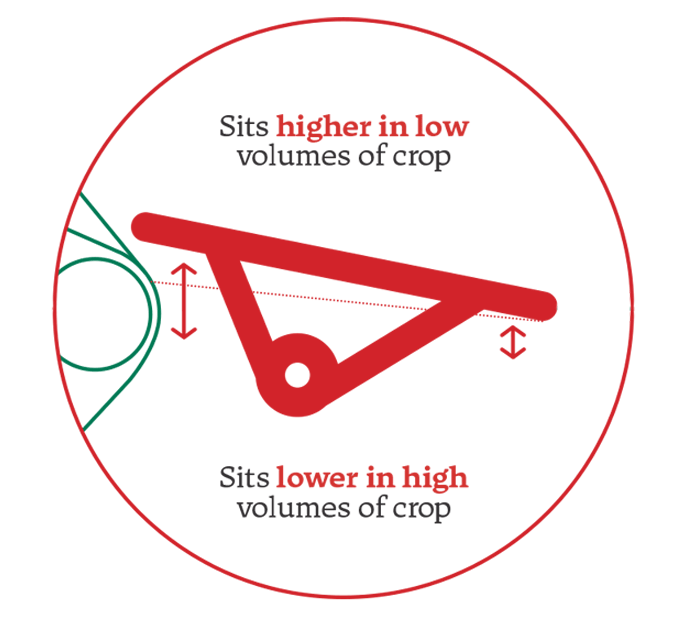

Over the course of a baling season, machines have to work with different volumes of crop. The McHale patented adaptive intake allows the intake area to automatically adjust for light and heavy crops to facilitate a smooth crop flow into the chamber.

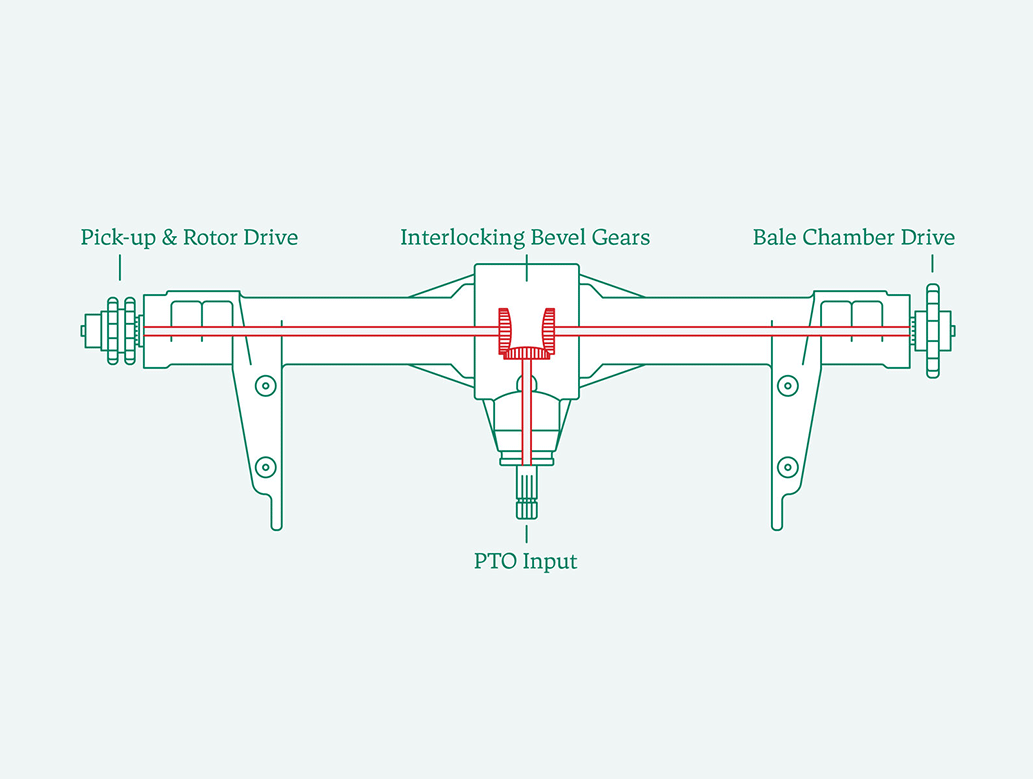

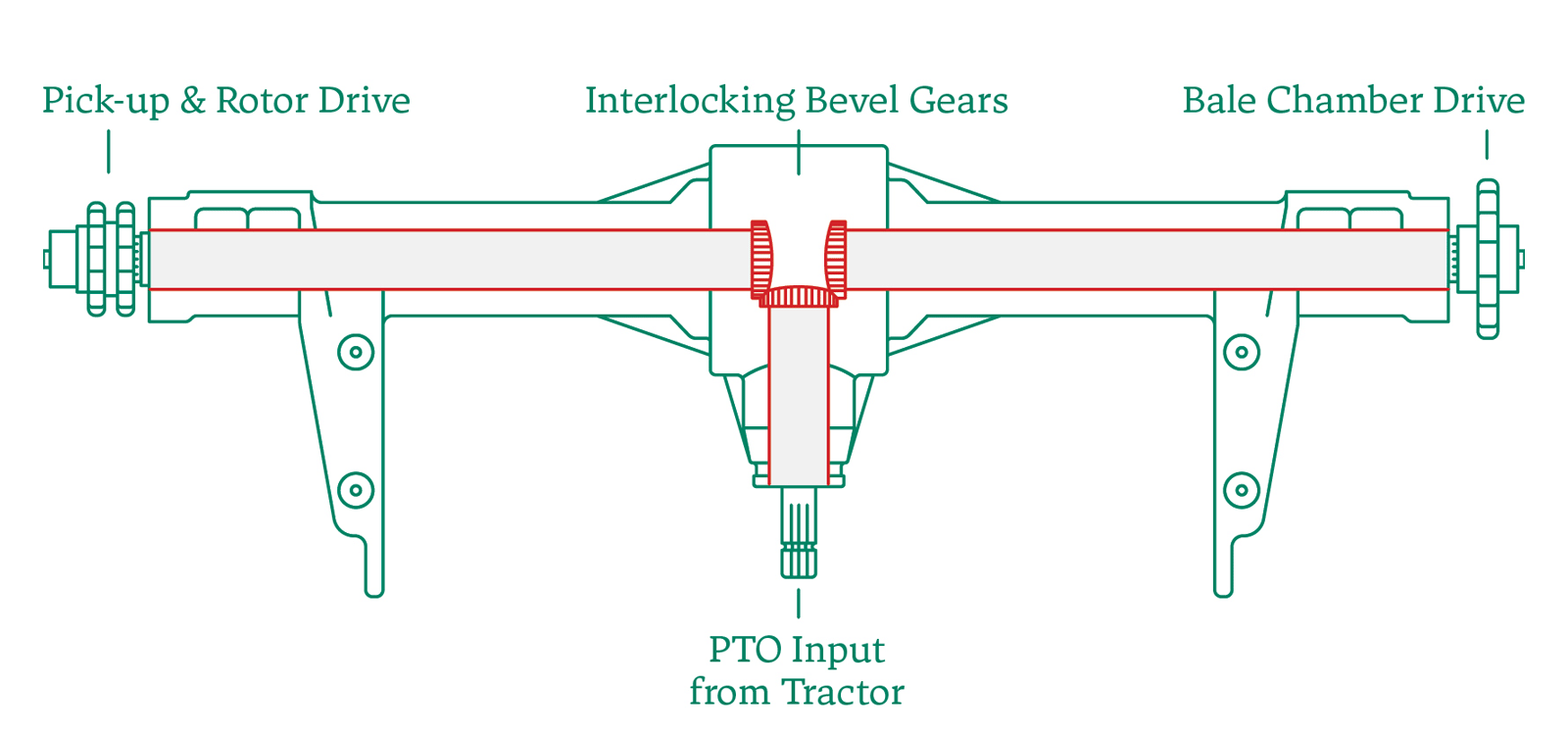

All machines in the McHale Variable Chamber Baler range come fitted with a 540 rpm split drive gearbox as standard. The gearbox design ensures that power is evenly distributed to both sides of the machine.

McHale machines work in different conditions around the world. In order to optimise machine performance, a 1000 rpm gearbox is available as an option on all Variable Chamber Baler range machines. The 1000 rpm gearbox provides the following advantages:

• The 1000 rpm gearbox results in an increase in PTO speed with a substantially reduced torque. This reduces the sharp loads on the drive line, allowing the clutch setting with 10% more capacity.

• The option to select a lower PTO speed (if available) on the tractor for easier restarts in the unlikelihood of blocking.

• Excellent fuel economy is achieved due to lower tractor engine revs, by running the machine at the nominal PTO speed of 900rpm when using a 1000 rpm box.

The rollers in the bale chamber are driven from the left-hand side of the machine and the pick-up and chopper unit are driven from the right-hand side of the machine. This system ensures direct, short transfer paths, leading to optimal power distribution to provide more torque and aid in the reduction of blockages.

In order to optimise machine performance, a 1000rpm gearbox is available as an optional upgrade on all machines in the McHale Variable Chamber Baler range.

We recommend you speak with your local dealer or distributor regarding which gearbox is best suited to your requirements, based on your working conditions.

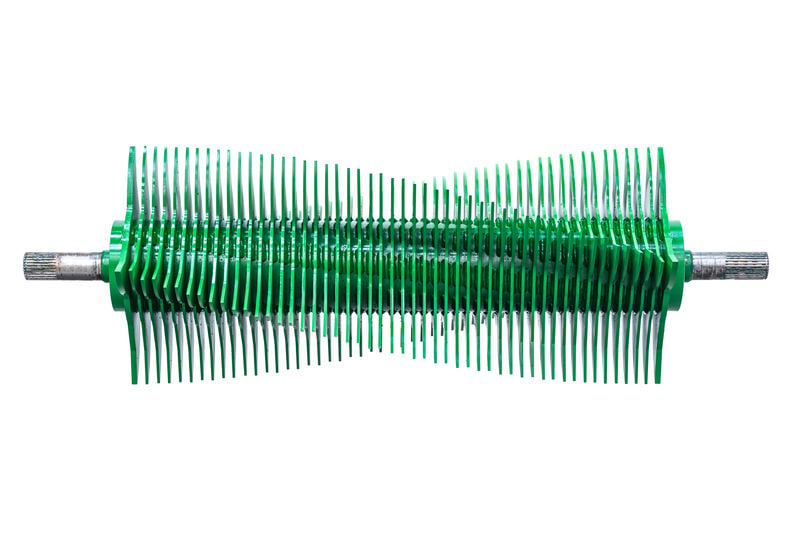

The star shaped feed rotor ensures a high-capacity flow of crop into the bale chamber. The flights on the rotor are laid out in a spiral formation to achieve consistent crop flow. As crop enters the rotor, rotating flights feed the crop to the bale chamber.

The flights on the rotor are laid out in a spiral formation to achieve consistent crop flow. As crop enters the rotor, rotating flights feeds it to the bale chamber. These ensure high output, while the star layout reduces the load peaks as the machines work in heavy swaths.

| Rotor Formation | Spiral |

| Flight Thickness | Inner: 8mm

Outer: 12mm |

| Number of Knives | 15 |

| Selectable Knives | N/A |

| Rotor Formation | Spiral |

| Flight Thickness | Inner: 6mm

Outer: 12mm |

| Number of Knives | 25 |

| Selectable Knives | Optional |

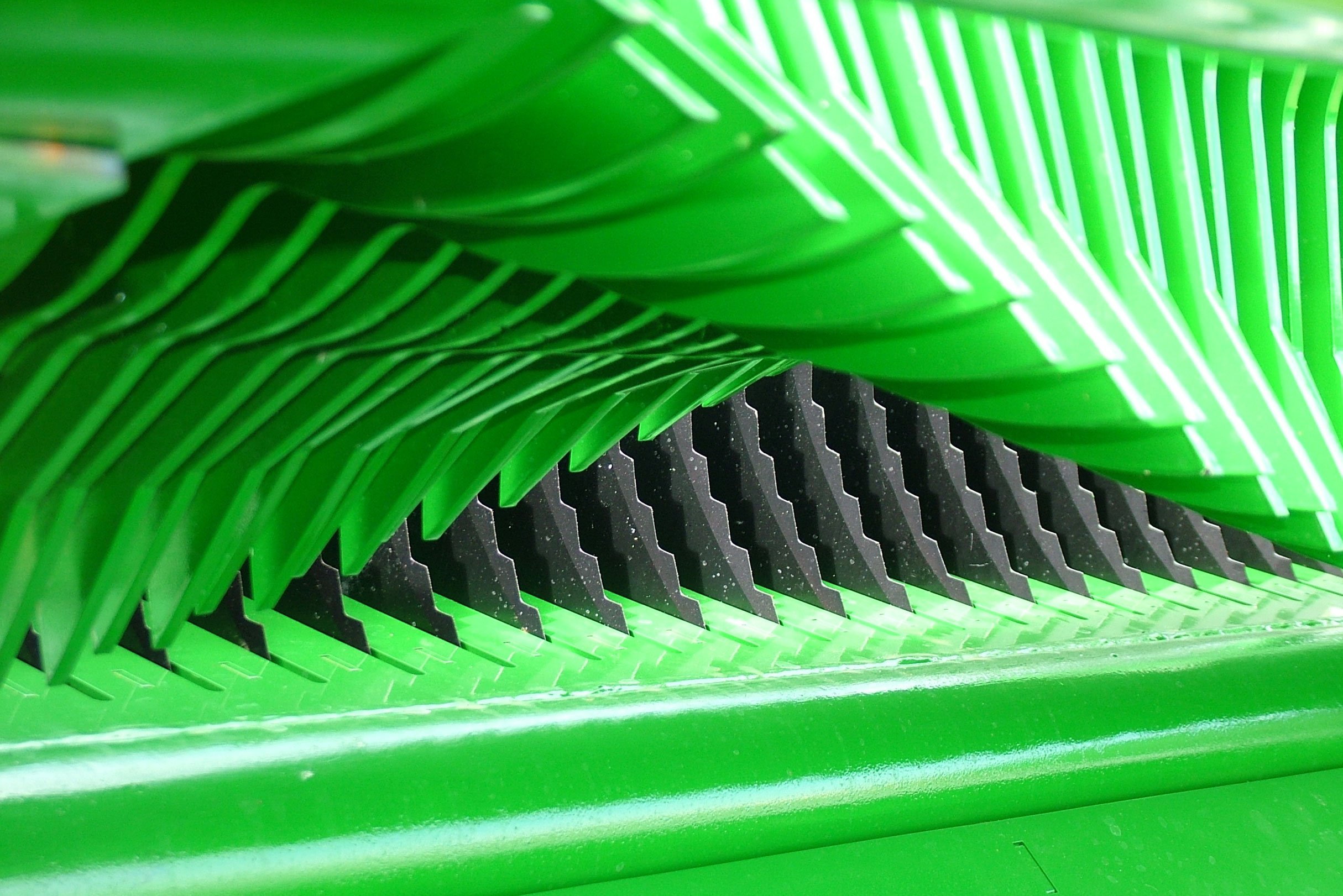

To ensure a consistent and even chop quality, two chopping options have been developed for the McHale Fusion Vario Plus Range.

| The 15 knife chopper unit is the standard chopper unit on the McHale Fusion Vario Plus. A bank of 15 knives provides a chop length of approximately 65mm. | |

| Flight Thickness | Inner: 8mm

Outer: 12mm |

| Number of Knives | 15 |

| Selectable Knives | N/A |

| The 25 knife chopper unit is available as an option on the McHale Fusion Vario Plus. A bank of 25 knives provides a chop length of approximately 46mm. | |

| Flight Thickness | Inner: 6mm

Outer: 12mm |

| Number of Knives | 25 |

| Selectable Knives | Optional |

All McHale Fusion Vario Plus machines have the option to be fitted with a selectable knife system. Various knife configurations can be chosen depending on the knife bank specification.

25 Knife Bank Options0, 12, 13, 25 Knives |

With selectable knives, the operator can vary the chop length by engaging or disengaging either knife bank. If fine chopping is required, the operator can choose to engage both knife banks. Should a longer chop length be required, the operator can disengage one bank of knives from the comfort and safety of the tractor cab on ISOBUS machines.

When using both knife banks separately, if the first bank of knives become blunt, the operator can lower the first knife bank and raise the second bank. This reduces the downtime and allows the operator to continue working. By having consistently sharp knives, fuel consumption is reduced and the machine always delivers optimum chop.

A new sharp set of knives can be engaged, without the operator having to physically replace knives, ensuring a well chopped crop and continued high output. Should different chop lengths be required the operator can make the adjustments by engaging or disengaging the knife bank without having to leave the tractor cab on ISOBUS models only.

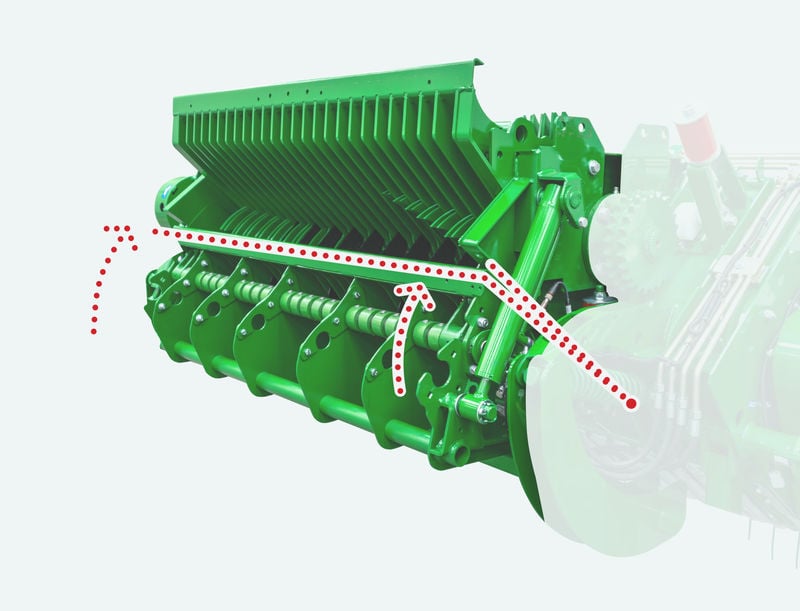

As baling conditions are not always ideal, uneven swaths can occur which can lead to blockages. All machines in the McHale Fusion Vario Plus range are fitted with the McHale drop floor unblocking system, a feature which operators have come to love for its simplicity of use and effective unblocking cycle.

Should a blockage occur, the sound of the slip clutch alerts the operator, who can hydraulically lower the floor from the tractor cab.

This widens the feed channel and on re-engaging the PTO, the blockage can be fed through.

The floor can then be reset to its original position and baling can resume

The drop floor unblocking system has a number of novel features which aid the operator and the performance of the machine to handle uneven swaths which can lead to blockages.

A fully automated unblock sequence is available on all V6760, V8960 and Fusion Vario Plus machines. If the machine is connected via an ISOBUS tractor, the drop floor and knives will lower automatically when the software detects a blockage and the operator disengages the PTO.

A prompt is then displayed to the operator to re-engage the PTO in order to clear the blockage, after which the drop floor will automatically reset to the working position and baling can resume.

On a non-ISOBUS tractor, the operator must disengage the PTO and lower the drop floor. After the PTO is re-engaged and the blockage is fed through, the drop floor and knives will automatically raise into position.

On the McHale Variable Chamber Baler Range, the drop floor is equipped with a sensor to ensure the chop quality is consistent by indicating to the operator via the control terminal if the drop floor is even slightly open.

This feature can be enabled on the V6760, V8960 and the Fusion Vario Plus. This allows the operator to chop the grass until the bale is almost complete, at which point the machine will automatically drop out the knives.

Depending on the feeding method, this improves fodder distribution, keeping the bale neater when the net or film is removed.

When baling hay or straw, operators have the ability to select a Density “0” setting on the control terminal. This reduces hydraulic pressure to zero and bale density is applied using springs only, which allows much lighter bales to be made.

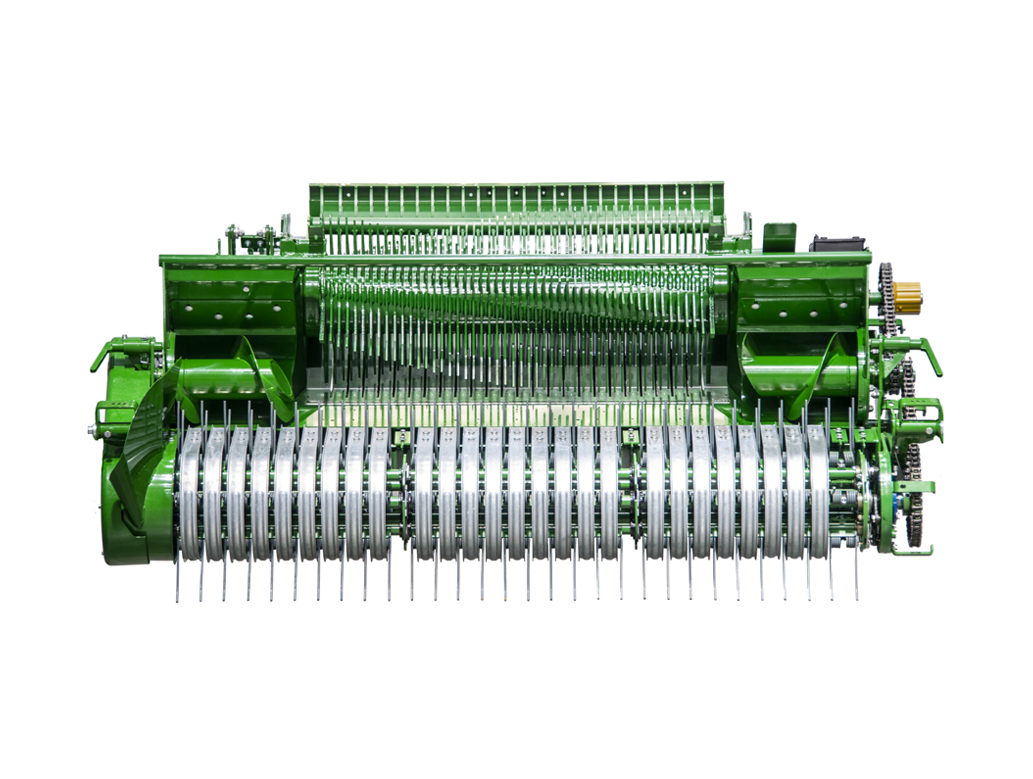

The bale chamber on the McHale variable chamber baler range is comprised of heavy-duty endless belt(s). The belts are extremely hard wearing and are reinforced with synthetic material, which ensures that the belt(s) can absorb and apply high pressure to the material in the Bale chamber.

Bale SizesThe Fusion Vario Plus can make a bale from 0.6m (2 ‘) to 1.68m (5 ‘6″) but in haylage or silage, produces bales from 1–1.45m

|

Size IncrementsThe bale size can be adjusted up from the minimum setting in increments of 10mm (2/5″) |

Single BeltA single full width endless belt is standard on the Fusion Vario Plus. This full width belt reduces crop loss, particularly in alfalfa and provides better belt traction for the operator compared to multiple endless belts. |

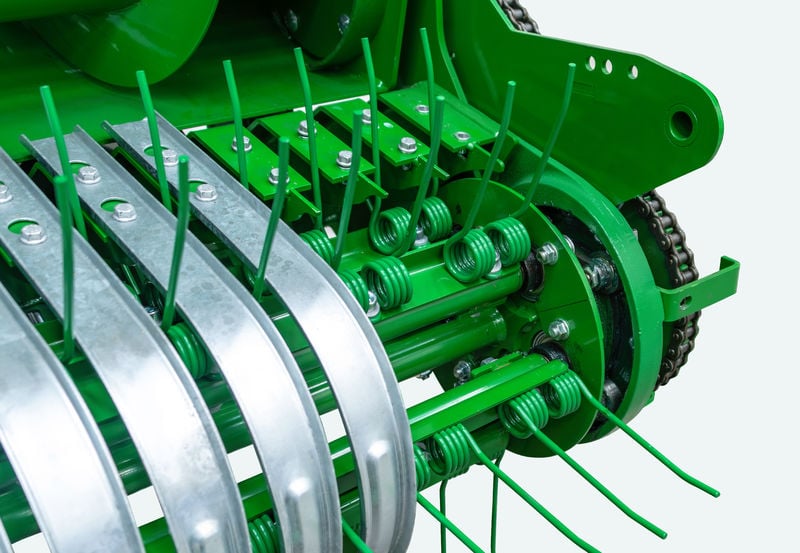

McHale have developed a bale chamber that can quickly form the bale from the start. The operator can commence baling at full speed as the progressive density system can quickly adjust to ensure that pressure is exerted on the crop right from the core of the bale, regardless of bale size.

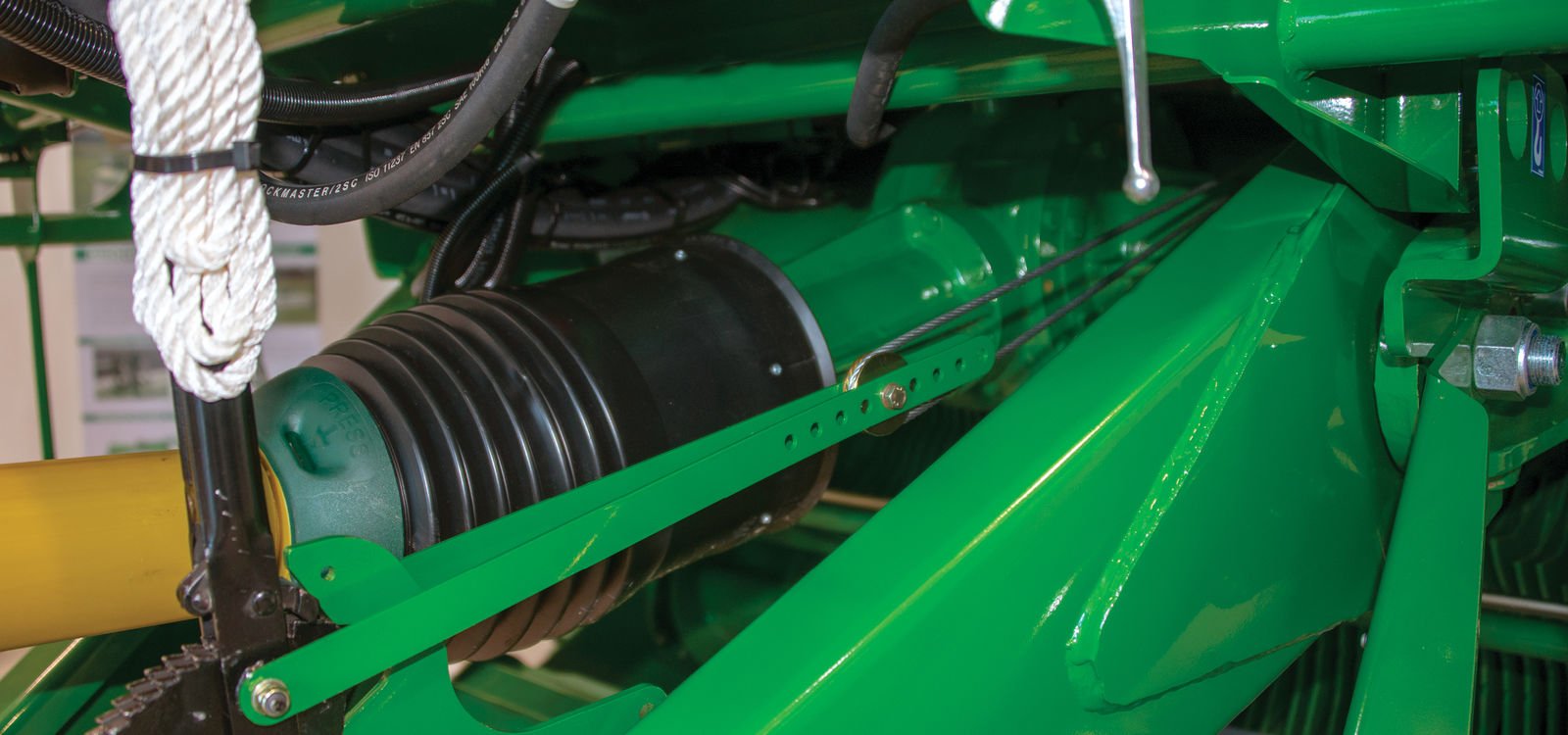

This is done by four heavy-duty springs that pressurise the crop at the start of the baling process. The tension placed on the crop by these large springs allows for the perfect start to the bale. The spring tension on the belts ensures easy bale formation and a properly formed core.

As the bale is forming inside the chamber, the hydraulics take over the tensioning of the belt(s) from the four large springs. Two hydraulic rams control the tension on the chamber belt(s) as the bale forms inside the chamber.

Just like the core of the bale, the outer layers are compressed at the same consistent pressure using both springs and hydraulics until the set bale density and size is reached.

A heavy-duty drive system powers belt and bale rotation on all machines in the variable chamber baler range. On the McHale Fusion Vario Plus, a double drive system is fitted to ensure belt rotation and bale formation.

In more difficult conditions, such as wet heavy grass, if the primary drive slips slightly, the double drive will engage in order to aid belt and material rotation in the chamber. This double drive helps bale formation as a constant pressure is kept on the chamber belts which results in the production of a solid and uniform bale even when dealing with a wet and heavy crop.

A cleaning auger is fitted to the double drive system in order to prevent crop build up and allow the double drive to aid bale rotation when working in wet or sugary crops.

All machines equipped with ISOBUS (V6750 with ISOBUS, V6760 & Fusion Vario Plus) and all machines in the V8 range are fitted with load cell bale shape assist indicators that directly measure the bale pressure inside the chamber.

By comparing the loading on each side of the chamber, the bale shape is calculated and then indicated to the operator via the control console, which side of the chamber needs to be filled.

This direct measuring of the chamber pressure allows the bale shape indicators to be extremely accurate and responsive.

The tailgates on all McHale variable chamber balers are fitted with a pair of mechanical locks, which keep the bale chamber securely closed. These locks remain activated until, the progressive density system reaches the preset bale size and density and the required amount of net has been applied. This eliminates the need for the chamber door to rely on hydraulic pressure when making high density bales.

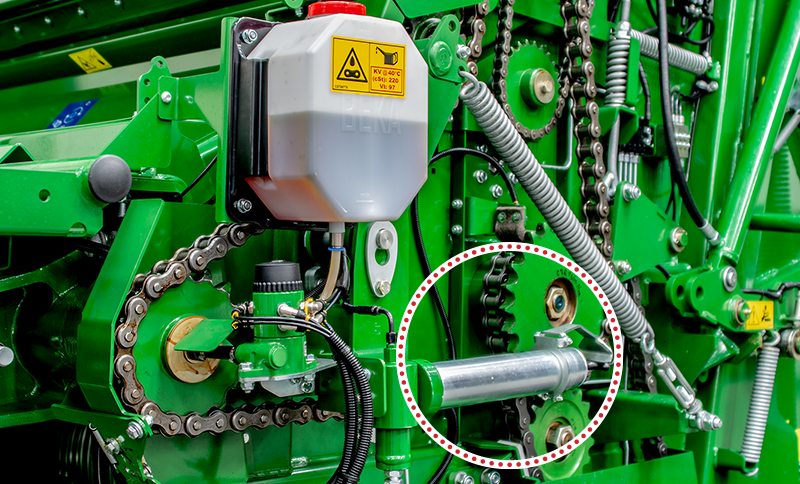

The McHale variable chamber baler range of balers are all fitted with a continuous oiling system. Once the PTO is engaged, the continuous oiling system constantly lubricates the chains to ensure a long lifetime. A lube alarm sounds after 300 bales to inform the operator to refill the oil tank.

The continuous oiling system on the machine is driven off the gearbox and delivers oil to the following chains:

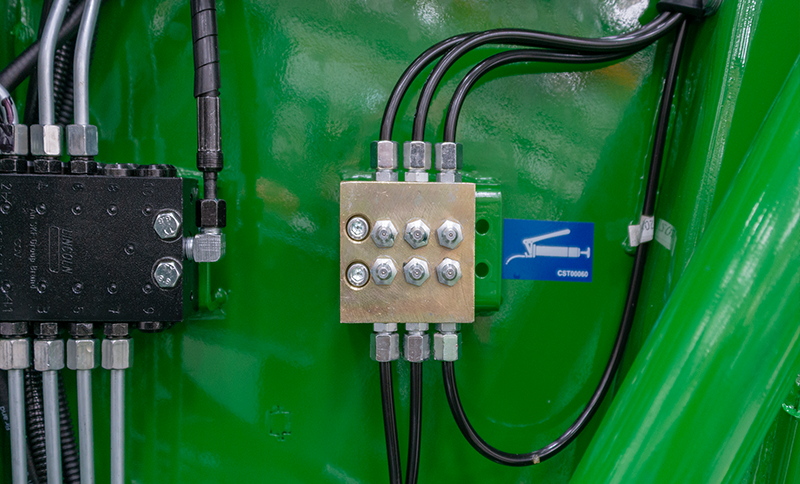

All machines come fitted with a number of manual greasing points which are easily accessible throughout the baler either individually or through a centralised greasing block. The following components are greased:

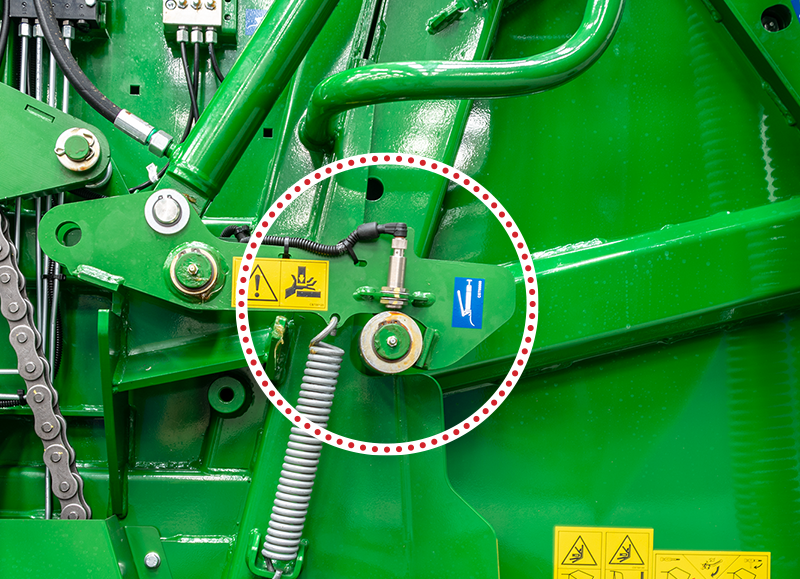

Automatic greasing is standard on all McHale Fusion Vario Plus machines.

The McHale Fusion Vario Plus is fitted

with a new automatic twin pump lubrication system which has a separate pump for grease and oil. This allows the oiling rate to be adjusted independently by the operator without affecting the greasing rate.

This pressurised system delivers a measured amount of grease around the machine after every bale cycle. Automatic greasing saves time as it reduces the amount of manual greasing to be done by the operator. The grease cartridge should be refilled after 1200 bales.

Film binding technology refers to the application of film to the barrel of the bale in the bale chamber. The film binds the bale together which eliminates the need for string or net wrap. It also forms a wrapping layer and gives better film or plastic coverage on the largest surface of the bale.

Patented Film Binding

In the development of McHale’s film on film technology, we realised that changes in temperature and sun light could affect the chamber wrapping film; as the day got hotter or cooler the film was either being over-stretched or under-stretched, and this in turn would cause reliability problems and result in inefficient film use.

As a result, McHale developed a patented application system which adjusts the braking force on the roll of plastic in-line with working conditions. This allows for a continuously variable stretch, which can automatically adjust to changes in the day, without the operator having to adjust any settings.

The McHale patented film application system ensures consistent film stretch, reliable film application and delivers optimum bale shape and bale density. Should an operator wish to use net wrap for hay or straw, this can be done with a simple changeover.

The plastic which is added to the barrel of the bale to keep the bale together also forms part of the wrapping process. This adds value by placing more plastic on the largest surface of the bale.

When plastic is applied to the barrel of the bale, it can be stretched to the manufacturers recommendations, which is a higher ratio than can be achieved with net wrap or twine and as a result, the material is kept tighter, which ultimately results in better bale shape.

As the plastic is being stretched during application to the barrel of the bale, it expels more air than net wrap does and as a consequence, results in better silage quality.

As plastic is used to both bind the bale in the bale chamber and to wrap the bale, on feed out, the farmer will be left with one form of waste. This reduces the time needed to feed the bale and avoids the unpleasant and time-consuming job of separating the twine or net wrap from the plastic before the plastic is recycled.

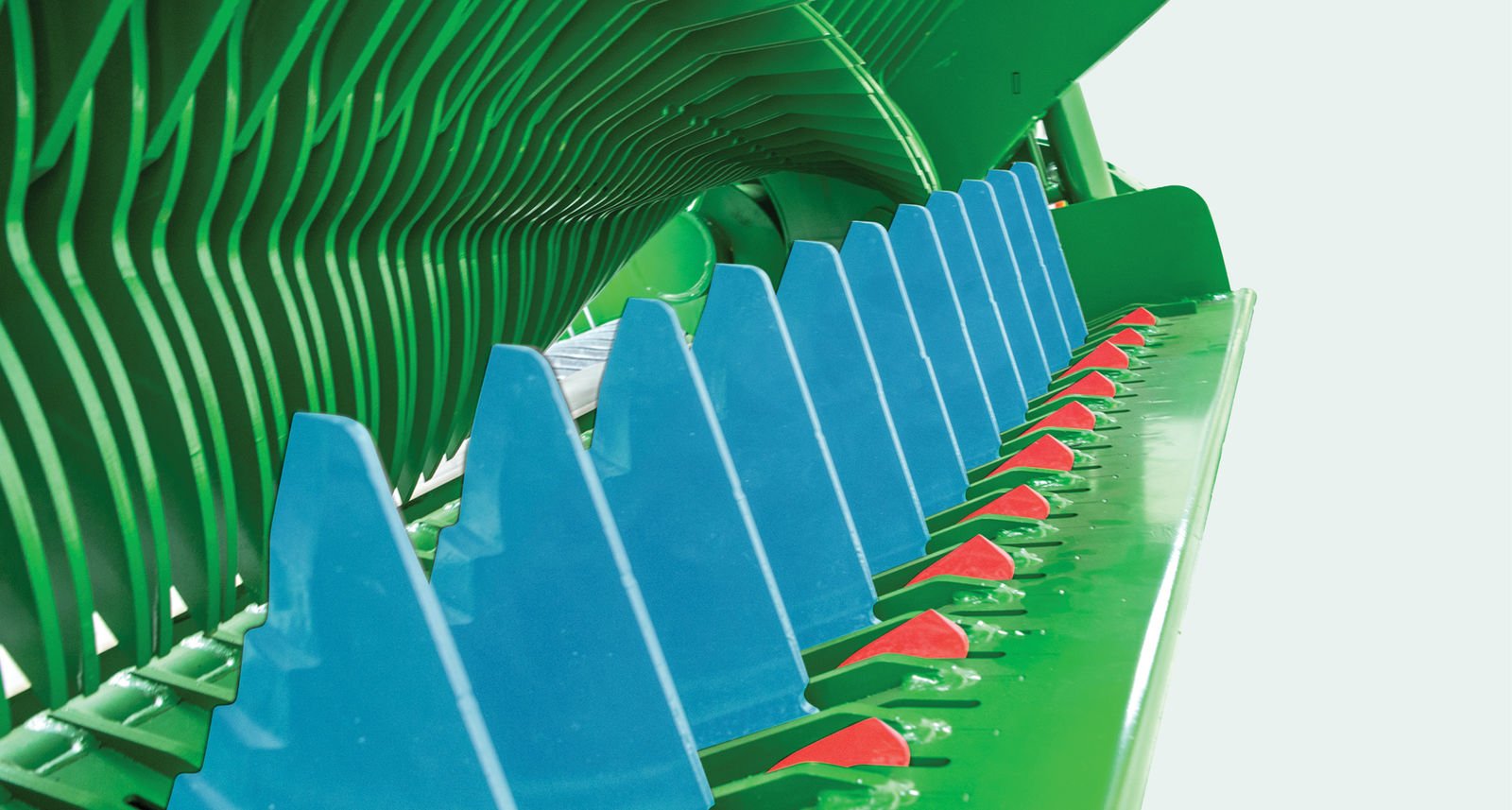

Two high performance binding systems have been designed & developed to ensure optimum performance. The McHale V6 & V8 series are equipped with a high performance netter while all Fusion Vario Plus machines are fitted with an infinite stretch hydraulic binding system.

Binding Material Stretch Application

The Fusion Vario Plus can either apply net or film to the barrel of the bale. This system ensures efficient net or film usage and that a tight layer of net or film is evenly applied to the bale. The net or film tension can be adjusted depending on the operator’s requirements. To obtain the desired stretch, a large net/film brake has been fitted to all machines in the variable chamber baler range, which provides 25% more stretch to be easily achieved. This is especially effective when operating in cold weather with film that requires a higher stretch percentage

Direct Beak Binding

The McHale Fusion Vario Plus is fitted with a new Direct Beak Binding system which maintains a permanent grip on the net or film. This system is very positive and facilitates reliable binding and cutting actions for both net and film. The new binding system features a beak which pivots upwards and away from the chamber to prevent any issues with crop accumulation during the baling process. During the binding process, it pivots downwards to actively place the net/film inside the chamber before it spreads full width for uniform coverage across the bale for consistent and accurate binding.

Net / Film Layers

The number of layers of binding material being used can be easily adjusted as the machine passes through different crop conditions. Net/film adjustment can be controlled from the control console in the tractor cab. At the touch of a button, the operator can easily adjust the stretch and the number of layers of net/film.

The operator can select bale diameter and the number of layers of net to be applied from the control console. The machine will automatically adjust the net application for different bale diameters.

Net/ Film Loading and Storage

The operator simply releases the straps on the spare roll of net/ film from its storage position on the machine and moves the roll into position. To aid the loading process for the operator, the roll of net/film can be placed in the loading cradle whilst being threaded through the binding unit. Once in position, the operator moves the tension bar to hold the roll in place. Storage for two extra rolls of net is provided on the baler platform on all V6 & V8 machines while storage on the Vario Plus is inside the panel on the side of the machine and on the front of the platform

Endless adjustment of tension to ensure optimum material usage and bale shape

Capacity to take rolls of net wrap up to 1300 mm in width and 4500m in length.

180-degree wrap around on the rubber feed roller, eliminating any net or film slippage while feeding

All McHale Fusion Vario Plus machines are ISOBUS compatible as standard. McHale ISOBUS machines can be plugged into any ISOBUS tractor connection and operated via the tractor’s own terminal in the cab.

The machine is connected via the tractor’s ISOBUS connector, which eliminates large cables being routed through the back window of the tractor cab. Alternatively, with an ISOBUS tractor, the operator can use a separate ISOBUS terminal.

The ISOBUS control terminals, when combined with the load sensing valve on the McHale Fusion Vario Plus, is capable of making baling and wrapping fully automatic. From knife and floor control, right through to bale ejection and tipping, the entire process is fully automatic.

The ISOBUS control terminals allow for the bale density to be adjusted from the comfort of the tractor cab. From the control terminal, the operator can adjust the number of layers of net or film being applied to the bale. On the McHale Fusion Vario Plus, the operator can also adjust the stretch being applied to the film in the bale chamber from the control terminal in the tractor cab.

The Auto Knife Drop feature is available

on all fully automatic machines to allow

for the operator to chop the forage until

the bale is almost complete, at which point the machine will automatically lower the knives. Depending on the feeding method, this can improve fodder distribution and machine intake.

If the customer wishes to operate an ISOBUS controlled machine with a tractor that is not ISOBUS compatible, they can do so through the optional McHale ISO-PLAY terminal.

McHale offer two ISO-PLAY monitor options.

Customers can purchase a McHale ISO-PLAY 7 or ISO-PLAY 12 control terminal, which can be used to operate the functions of other ISOBUS machines. Should the customer already own an ISOBUS control terminal from another machine this then can be used to control the functionality of the McHale balers. Through the ISOBUS tractor’s terminal or McHale’s ISO-PLAY terminals, the operator is provided with clear indicators of machine performance and allows for increased levels of monitoring, through the graphic display.

When operating the machine in manual mode, an image of the machine is displayed which allows the operator to select the relevant functions to control. In each function there is an information button that, when pressed, will show the current state of the function, for example:

All ISO-Play control consoles are fitted with Smart Switching camera functionality as standard.

On the McHale Fusion Vario Plus, the Smart Switching Cameras view the binding process in the chamber and the wrapper at the rear of machine. In automatic mode on all ISO-Play consoles, the camera image will appear at intelligent times on the screen during the baling cycle rather than on a time-based system, on existing machines. If required, the operator can manually switch between the two camera displays.

The smart switching cameras can also be fully customised by the operator to suit their preferred view for when the bale is being bound, transferred or being tipped.

A Virtual Density Gauge is displayed on the screen of the connected ISOBUS terminal. This allows the operator to view the density of the bale being produced on screen rather than on the machine body.

During the baling process, a bale size indicator shows the driver how the bale is forming in the chamber. When the desired density is achieved on the graph, a “Stop” warning is signaled to the driver to notify them that crop should stop being fed into the chamber.

McHale machines work in different conditions around the world. To optimise performance, we offer a number of options in the McHale Fusion 4 range. We recommend you speak with your local dealer/distributor as regards the best features or options to meet your requirement

Fusion Vario Plus

| Camless Pick-Up | Optional |

| Chopper unit | 25 Knife Optional |

| Selectable Knives – 0,12,13,25 | Optional |

| 1000rpm Gearbox | Optional |

| Brakes | Hydraulic: Standard | Air: Optional |

| ISO-PLAY 7 or ISO-PLAY 12 |

Optional |

| Side Tip | Optional |

| Bale Weighing & Moisture System | Optional |

| Tyre Options | 680 / 50 / 22.5 |

Camless Pick-Up with Profi-Flo

The 2.1 m Profi-Flo camless pick-up runs smoothly, particularly in short crop, and requires less maintenance due to a reduced number of rotating parts. All camless pick-ups in the McHale Fusion range are fitted with six tine bars to provide excellent ground cleaning and fast delivery of crop to the rotor.

Rotor / Chopper Unit

The 25 knife rotor and chopper unit is available as an option on the McHale Fusion Vario Plus variable chamber machines and delivers a chop length of approximately 46mm.

Selectable Knives

A selectable knife system consists of two knife banks which allow for various knife configurations to be chosen depending on the knife bank specification. If a machine is equipped with 25 knives, then a bank of 12 and a bank of 13 knives are available to be chosen from. If chopping is not required, then the operator can select for no knives to be engaged. On all standard V6750 & V8950 machines, knife selection is engaged from the baler, while on ISOBUS/ ISO-Play machines in the variable chamber baler range, knife selection can be decided from the tractor cab.

1000rpm Gearbox

McHale machines work in different conditions around the world so in order to optimise machine performance, a 1000 rpm gearbox is available as an optional upgrade on all machines in the McHale baler range.

Brakes

All McHale Fusion Vario Plus machines come fitted with hydraulic brakes as standard but can be specified with air brakes as an optional extra.

ISO-PLAY 7 or ISO-PLAY 12

If the customer wishes to operate an ISOBUS controlled machine with a tractor that is not ISOBUS compatible, they can do so through the McHale ISO-PLAY 7 terminal, equipped with its 7” screen or the larger, 12” screen on the McHale ISO-PLAY 12 terminal which is also available as an optional extra. An additional tractor wiring loom is required to do this.

Bale Weighing & Moisture System

If the Fusion Vario Plus is fitted with the optional bale weighing system, the control terminal displays a bale weight icon on its main screen providing the calculated bale weight.

When fitted with the optional bale moisture recording system, a moisture icon will be shown on the main screen along with a live value showing the percentage of moisture in the crop being baled.

Tyre Options

McHale offer a number of tyre upgrades depending on customer preferences and ground conditions. Please see below for the tyre options available to suit your machine of choice:

| Option 1 |

| 680/50/22.5 |

The McHale Fusion Vario Plus is a fully automatic variable chamber integrated baler wrapper, which consists of a high output baler and a vertical wrapping ring. The machine benefits from two unique patents; a patented bale transfer system and a patented vertical wrapping ring.

In this episode of our Spotlight Series, we take a look at the new McHale Fusion Vario Plus which is now ISOBUS controlled and binds with either film or net.

| Diameter | 0.6 – 1.68m (2’–5’6″) |

| Width | 1.23 m (4′) |

| Bale Chamber Feed | 15 Knife Chopper Feed Rotor |

| Number of Belts | 1 |

| Number of Knives | 15 |

| Theoretical Chop Length | 65 mm |

| Unblocking System | Automatic Drop Floor** |

| Knife Activation | Electronic Control |

| Knife Protection | Hydraulic |

** When connected to an ISOBUS enabled tractor

| Working Width | 2100mm (6’11”) |

| Tine Bars | 5 (6 on Camless Pick-up) |

| Tine Spacing | 67mm (2 5/8”)

Camless: 55mm (2 1/8”) |

| Crop Roller | Standard |

| Pick Up Guide Wheels (pneumatic) | Standard |

| Binding Material |

NRF or Net |

| Control | Automatic or Manual |

| Binding System | Direct Beak Binding |

| Bind Roll Capacity | 1 + 2 Storage |

| Bind Adjustment | In Cab |

| Gearbox |

Split Drive |

| Pick Up Protection | Slip Clutch |

| Main Drive Protection | Cam Clutch |

| Chain Lubrication | Continuous |

| Bale Chamber |

Double Drive |

| Control System | ISOBUS |

| Operation | Fully Automatic |

| Density Adjustment | In-Cab |

| Bale Size Adjustment |

In Cab |

| Inbuilt Camera | 2x Inbuilt Camera |

| Axle | 8 stud |

| Brakes |

Standard: Hydraulic (Option: Air) |

| Tyres Standard | 650/50/22.5 |

| Tyres Optional | 680/50/22.5 |

| Bale Kicker | N/A |

| Side Tip | Option |

| Road Lights | Standard |

| Length | 6.3m (20’8″) |

| Width | 2.94m (9’8″) |

| Height | 3.3m (10’10”) |

| Weight | 6500kg* (14,330 lbs) |

* Value will vary depending on specification

| Minimum Hydraulic Flow | 45 l/min @ 180 bar |

| Hydraulic System | Open Centre, Closed Centre or Load Sensing |

| Electronics |

12 Volt DC, 20 amp |

| Minimum Power Requirements | 85kW (114hp) |

Customer Testimonial 1

In this episode of our Spotlight Series, we take a look at the new McHale Fusion Vario Plus which is now ISOBUS controlled and binds with either film or net.

Customer Testimonial 2

In this episode of our Spotlight Series, we take a look at the new McHale Fusion Vario Plus which is now ISOBUS controlled and binds with either film or net.